Why Expansion Joints in Piping Are Critical for System Longevity

Expansion joints in piping systems help absorb thermal movement, mitigate vibration, and prevent premature system failures. This article discusses their critical role across industries and offers guidance on selecting the right solution from Resistoflex.

Introduction

Expansion joints in piping systems are not auxiliary componentsthey are structural necessities. Whether in industrial plants, commercial buildings, or infrastructure pipelines, these joints safeguard the system from thermal expansion, vibration, and mechanical stress.

In this article, we examine the purpose, benefits, and applications of expansion joints in piping, along with a technical reference to a detailed article:

How Expansion Joints Enhance Piping System Reliability

1. Understanding Expansion Joints in Piping

Expansion joints are engineered components that allow controlled movement in piping systems. They are designed to absorb:

-

Thermal expansion and contraction

-

Mechanical vibrations

-

Misalignment due to structural shifts

These joints maintain the structural integrity of the pipeline while minimizing operational stress.

For more insights, explore our complete range here:

Resistoflex Expansion Joint Solutions

2. Importance of Expansion Joints in Industrial Systems

Without expansion joints, pipelines are prone to:

-

Thermal stress leading to deformation

-

Leakage at pipe joints

-

Excessive wear on connected equipment

-

Downtime due to unexpected maintenance

In industries where reliability is paramount, such as oil & gas, HVAC, and chemical processing, expansion joints in piping play a vital role in sustaining performance.

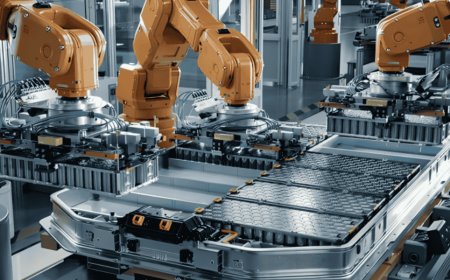

3. Types of Expansion Joints Offered by Resistoflex

Each type serves specific mechanical and environmental demands:

-

Rubber Expansion Joints: Flexible, corrosion-resistant, and suitable for fluid transport in HVAC and pump systems

-

Metal Expansion Joints: Designed for high-pressure and high-temperature conditions

-

Flexible Pipe Connectors: Ideal for absorbing small movements in pump and compressor lines

Learn more about each type here:

Resistoflex Expansion Joint Range

4. Key Application Areas

Expansion joints are used across sectors:

-

HVAC systems

-

Power plants

-

Water treatment facilities

-

Petrochemical pipelines

-

Firefighting systems

These joints accommodate environmental variations while preventing structural fatigue.

Reference article:

How Expansion Joints Enhance Piping System Reliability

5. Risks of Not Using Expansion Joints

Neglecting expansion joints in piping systems can result in:

-

Pipe rupture due to uncontrolled expansion

-

Excessive vibration causing noise and wear

-

Flange leaks and equipment misalignment

-

Costly repairs and operational downtime

Incorporating the right expansion joint prevents these risks and supports smooth operation.

6. Selecting the Right Expansion Joint

Key considerations include:

-

Operating temperature and pressure

-

Pipe diameter and layout

-

Type of fluid being transported

-

Movement requirements (axial, lateral, angular)

Professional consultation ensures optimal product selection.

Connect with our team: sales@resistoflex.in

Conclusion

The role of expansion joints in piping is often underestimated until failure occurs. Investing in quality expansion joints from the start significantly improves system reliability, reduces maintenance costs, and extends the lifecycle of equipment.

For further technical reading, visit:

How Expansion Joints Enhance Piping System Reliability

Explore our full product line:

Resistoflex Expansion Joint Products