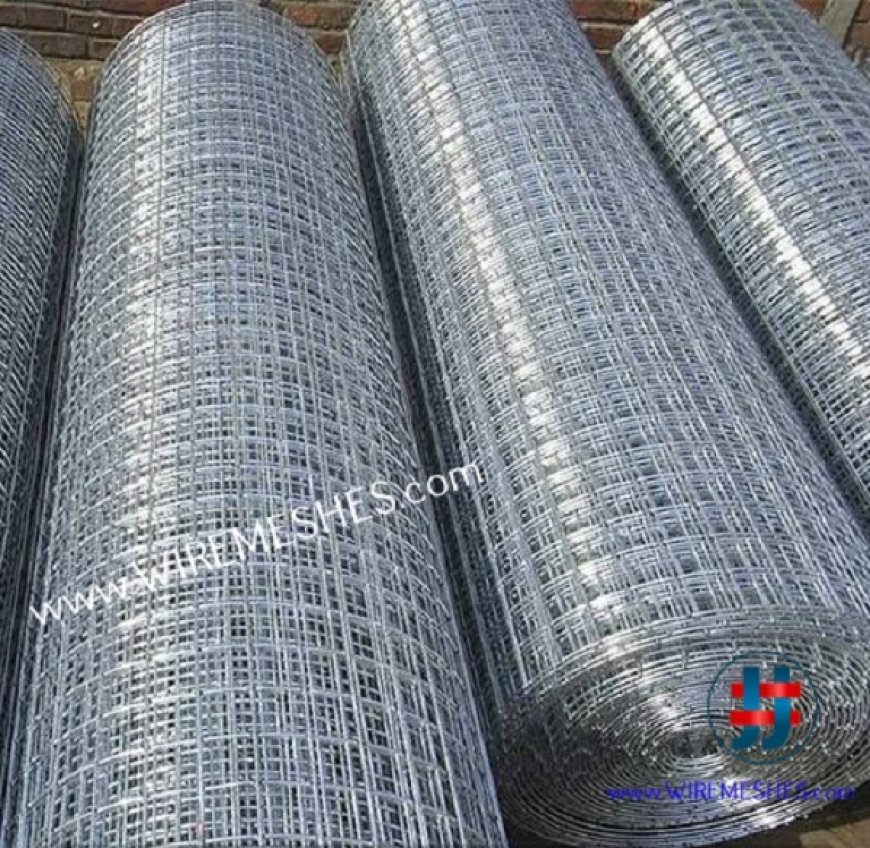

Welded Mesh Manufacturers: Choosing the Right Partner for Superior Quality

Choose the right welded mesh & MS expanded metal manufacturers with tips on quality, customization, applications & ROI for industrial to agri use.

When it comes to metal mesh solutions, finding reliableWelded Mesh Manufacturers is critical. Whether youre working on architectural installations, security fencing, or industrial filtration systems, choosing the right manufacturer impacts performance, durability, and cost-effectiveness. In this blog post, well explore what defines top-tier welded mesh manufacturers, the benefits of collaborating with MS Expanded Metal Manufacturers, and how integrating both welded and expanded mesh can elevate your next project.

Why Welded Mesh Manufacturers Matter

Welded mesh is manufactured by joining intersecting steel wires at every crossing point through automated electric welding. This process produces a grid-like structure that is stronger and more stable than woven wire mesh, offering distinct advantages.

Superior Strength & Structural Integrity

Welded mesh panels are rigid and robust, thanks to their welded junctions. Choosing experienced Welded Mesh Manufacturers ensures consistent weld quality, minimizing weaknesses and increasing load-bearing capacity.

Precision & Customization

Top-notch manufacturers offer precise wire spacing, thickness, and mesh size. Whether you need a decorative architectural panel, a livestock fencing panel, or a safety railing, experienced Welded Mesh Manufacturers can tailor specifications to suit your application.

Cost Efficiency & Durability

With minimal waste, predictable production, and longer lifespan, welded mesh represents a cost-efficient investment. Reliable manufacturers also offer surface finishes like hot-dip galvanizing or powder coating, extending corrosion resistance.

Who Are MS Expanded Metal Manufacturers?

You may already rely on welded meshbut expanded metal offers unique advantages. MS Expanded Metal Manufacturers produce metal sheets that are simultaneously slit and stretched, forming diamond or hexagonal patterns. This creates strong, lightweight panels ideal for:

-

Walkway grating

-

Fencing with visibility

-

Agri-industrial applications

-

Decorative facades

-

Protective machine guarding

Combining welded mesh and expanded metal gives you the flexibility to pick the ideal format for each project requirement.

Welded Mesh vs. MS Expanded Metal A Comparative In

Choosing between welded mesh and expanded metalosightr combining bothdepends on your specific needs. Heres how each fares:

| Feature | Welded Mesh | Expanded Metal |

|---|---|---|

| Rigid Structure | Rigid and flat | Flexible depending on sheet thickness |

| Fabrication Process | Fused wires at intersections | Single sheet slit & stretched |

| Load Bearing | Stronger under direct load | Good shear strength, lighter weight |

| Surface Area | Open square/rectangular patterns | Diamond/hexagon patterns, more open area |

| Application Suitability | High-security fencing, structural panels | Walkways, grates, facades, lighter uses |

By selecting the right Welded Mesh Manufacturers or MS Expanded Metal Manufacturers, you align your materials precisely with project demands.

Key Considerations When Choosing Welded Mesh Manufacturers

To ensure you partner with the best Welded Mesh Manufacturers, consider the following criteria:

Material Quality & Standards

Check whether manufacturers use high-grade steel. Panels should conform to standards like ASTM A1064/A1064M or EN 10223-8. Reputable Welded Mesh Manufacturers will provide mill certificates and quality documentation.

Welding Technology & Equipment

Modern facilities employ robotic welding systems that ensure consistent welds and tight tolerances. Ask about welders capacity, welding current settings, and speed to assess precision capabilities.

Customization Options

Top-tier Welded Mesh Manufacturers offer custom panel dimensions, wire gauges, finishes (galvanized, PVC-coated), and specialty coatings. Evaluate how well they respond to custom drawings or samples.

Production Capacity & Lead Time

Projects often have tight deadlines. Look for manufacturers with scalable production lines and adequate stock of raw materials to fulfill large or urgent orders. Reliable Welded Mesh Manufacturers proactively manage lead times.

Post?Production Services

After production, coatings, cut?to?length services, CNC bending, and panel framing are valuable. Good Welded Mesh Manufacturers coordinate logistics and packaging to ensure safe delivery.

Exploring MS Expanded Metal Manufacturers

If your project includes expanded metal, its equally important to assess MS Expanded Metal Manufacturers by these factors:

Sheet Thickness & Open Area

Thickness (gauges from 0.7?mm to 6?mm) and percentage open area define panel strength and aesthetic. Top MS Expanded Metal Manufacturers will offer technical datasheets and product variants.

Pattern Type & Strand Width

Different diamond sizes and strand widths produce unique looks and structural qualities. Whether you need fine mesh for filtration or a bold faade pattern, choose an MS Expanded Metal Manufacturer with diverse pattern capabilities.

Mechanical & Surface Finishing

Besides galvanizing, manufacturers may offer stainless steel, aluminum, or specialty coatings like anodizing. These options impact corrosion resistance, reflectivity, and maintenance needs.

Applications & Case Studies

Heres how welded mesh and expanded metal get used in real projects:

Security Fencing Welded Mesh

High-security sitesairports, prisons, border fencinguse heavy-duty welded mesh with narrow apertures. Manufacturer-supplied meshes are hot-dip galvanized and optionally PVC-coated for stealth aesthetics.

Architectural Interiors Expanded Metal

Commercial interiors, stair risers, or design partitions often feature expanded metal. Light-transmitting, decorative, and structurally sound, these panels from certified MS Expanded Metal Manufacturers transform spaces with modern appeal.

Industrial Walkways Expanded Metal

In factories, platforms and walkways require slip resistance and drainability. MS Expanded Metal Manufacturers tailor sheet thickness and pattern to meet load codes and safety regulations.

Agriculture & Animal Enclosures

Outdoor pens and aviaries benefit from welded meshtough, easy to clean, and effective at containment. Look to Welded Mesh Manufacturers offering UV-resistant coatings and precise panel dimensions.

How to Work With Two Manufacturers Seamlessly

If your project requires both mesh types, heres a clear plan:

Define Material Roles

Outline project zonessecurity walls (welded mesh), equipment guards (expanded metal), decorative screens (both). This ensures you buy from qualified Welded Mesh Manufacturers and MS Expanded Metal Manufacturers.

Standardize Dimensions

Coordinate panel sizes, fixing details, and edge finishes across both manufacturers. This minimizes on?site adjustments and streamlines installation.

Confirm Finish Compatibility

Ensure coatings (galvanizing, powder coat) match across mesh types to achieve uniform appearance and corrosion protection. Ask for color-coordinated samples.

Coordinate Logistics & Delivery

Consolidating shipments or synchronizing deliveries reduces freight costs. Well?organized manufacturers communicate on packaging and timing.

Cost Factors & ROI

Smart procurement balances cost, quality, and service. Key cost drivers for Welded Mesh Manufacturers include:

-

Steel grade & coating

-

Wire diameter & mesh spacing

-

Welding strength

-

Panel size

-

Surface treatment

Similarly, MS Expanded Metal Manufacturers price on:

-

Sheet thickness

-

Open area ratio

-

Pattern complexity

-

Finishing options

While cheaper products may exist, lacking quality control can lead to costly replacements or failure. Investing slightly more in trusted manufacturers saves long-term.

Checklist Evaluating Welded Mesh & Expanded Metal Suppliers

Use this checklist when vetting manufacturers:

-

Do they meet relevant standards (ASTM, EN, IS)?

-

Can they provide mill certificates and welding reports?

-

How flexible are they with custom dimensions and finishes?

-

What is their minimum and maximum order size?

-

Do they offer post-production services (cutting, framing, delivery)?

-

Are coatings consistent between mesh types?

-

Can they meet your project schedule?

-

Do they support vendor coordination if you source both mesh types?

Final Thoughts

Working with top-notch Welded Mesh Manufacturers and MS Expanded Metal Manufacturers ensures your project meets structural demands, visual design needs, and maintenance goals. High-quality mesh enhances not only utility but also the professional appeal of any spacewhether industrial, architectural, or residential.

Next steps:

-

Draft a material spec sheet detailing wire sizes, finishes, and panel dimensions.

-

Request quotes from at least two manufacturers of each mesh type.

-

Ask for product samples to check weld strength or strand integrity.

-

Plan coordinated delivery and installation logistics upfront.