EPR for Plastic A Strategic Tool for Sustainable Innovation

EPR for plastic isn't just compliance—it's a catalyst for eco-friendly innovation and packaging transformation. See how your business can lead.

In today's eco-conscious market landscape,Plastic Waste EPR(Extended Producer Responsibility) has evolved from regulation into a powerful strategic lever. By holding manufacturers responsible for the entireEPR for Plasticlifecycle of plastic packagingfrom design to disposalEPR encourages innovation, efficiency, and circularity. With EPR Registration for Plastic, Plastic EPR Government Fee, and expert guidance from an EPR Consultant, EPR Registration Consultant, or Plastic waste consultant, companies can embed sustainability while simplifying compliance. Topping it off, a Plastic EPR Return Consultant, and especially the Number?1 consultant in EPR, help ensure proper reporting and certification. Lets explore how EPR is reshaping packaging and fostering sustainable innovation.

1. Why EPR Spurs Innovation

EPR adds the environmental cost of packaging into the product lifecycle, shifting incentives upstream to reward eco-friendly design and systems thinking. The OECD labels it a purpose-built strategy to promote the integration of environmental costsinto the market price

Studies confirm the impact:

-

EPR has driven a27?% increase in recycling?tech patentssince 2010

-

EU EPR schemes have cut landfill packaging by50?% in 20 years, with Germanys packaging recycling reaching 67?%, and 42?% specifically for plastics.

-

Swedens PET bottle recycling is at84.8?%

These figures highlight how EPR inspires durable materials, disassembly-friendly design, and recyclable packaging.

2. Strategic Shift: From Waste to Design

UnderPlastic Waste EPR, producers rethink packaging from the outset:

-

Design for Disassembly: simplifying material separation

-

Recyclable Materials: mono-materials and compostable alternatives reduce processing costs

-

Product-as-Service Models: leasing or refilling systems cut virgin production

-

Take-back Schemes: incentivize returns and close material loopsIt moves packaging from disposable to strategic assets.

3. Registration: The Foundation of Strategy

Before innovation begins, compliance must start.EPR Registration for Plasticis the gateway:

-

Indias CPCB/ SPCB portal allows PIBOs to register once they define the scope, planning, and documentation

-

Documents include GST, PAN, procurement/sales data, and agreements with collectors/recyclers

-

Fees are structured:

-

<?1,000?TPA ? ?10,000

-

1,00010,000?TPA ? ?20,000

-

?10,000?TPA ? ?50,000

Annual renewal and processing fees at 25?% apply

-

Smart businesses engage anEPR Registration Consultantto streamline documentation and avoid delays.

4. Fees: Funding Circular Infrastructure

ThePlastic EPR Government Feefunds sustainable waste management infrastructure and oversight:

-

Base registration fee + 25?% annual processing fee

-

Mid-size PIBOs pay ?20,000 + ?5,000 (renewal), while large ones pay ?50,000 + ?12,500.

-

These funds support collection, recycling, monitoring systems, and portal maintenance.

When supported by expertEPR Consultants, these fees become investments in sustainable operations, not mere costs.

5. Operationalizing Innovation Through EPR

Turning fees into action involves:

-

Engaging expert support: AnEPR ConsultantorPlastic waste consultantassists in plan development and system mapping.

-

Eco?design integration: Consultant teams use EPR incentives to propose recyclable packaging materials.

-

Process and partnerships: Working with registered Plastic Waste Processors (PWPs) via anEPR ConsultantorNumber 1 consultant in EPRaccelerates network access.

-

Reporting and verification: APlastic EPR Return Consultanttracks certificates and files data.

-

Review and refine: Annual performance data informs design tweaks and cost savings.

This method converts compliance into continuous improvement and cost-effectiveness.

6. Market Opportunities: Credits & Recycled Content

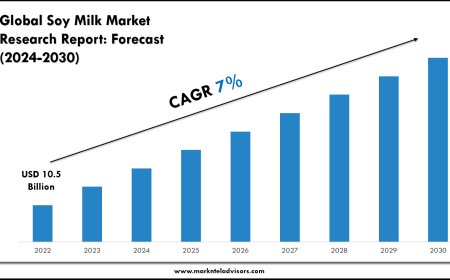

India's emergingplastic credit market, projected to reach$1.67?billion by 2030, hinges directly on EPR regulations pushing recycled content mandatesThis market:

-

Boost recyclate demand beyond compliance

-

Rewards innovators with surplus recycling certificate credits

-

Enables revenue or offsetting via credit trading

Working with anEPR Consultanthelps producers integrate into this market smartly.

7. Scaling Up Benefits for Businesses & Society

EPR-driven innovation offers multiple returns:

-

Technical advantage: Panthering bioplastics, disassembly technologies, and remanufacturing

-

Cost savings: Less virgin material reduces raw?material procurement costs

-

Brand strength: Sustainability resonates with modern consumers and B2B clients

-

Job creation and infrastructure: Circular systems attract new investments, formalizing waste economy

By strategically using fees and compliance, businesses flip regulatory burden into growth momentum.

8. Global Leadership: Examples & Inspiration

Countries with advanced EPR systems demonstrate success:

-

Germany: Packaging recycling of67?%, with plastic rates above42?%

-

Japan: PET bottle recycling success over93?%

-

France: Recycles68?% of packaging, 28?% of which is plastic

-

South Korea: Increased packaging recycling by70?% from 20032017

India actively invests in EPR and circular growthbut to make the most of it, innovation and consultancy are essential.

9. Overcoming Challenges with Expertise

EPR isnt without hurdles:

-

Complex multi-layer plastics remain difficult to recycle

-

Monitoring informal waste workers and building collector systems needs local understanding

-

Digital reporting and certificate management can overwhelm without support

Here, hiring a top-tierEPR Consultant,Plastic waste consultant, or theNumber 1 consultant in EPR, becomes key for unlocking full system value.

10. Adoption Roadmap for Strategic EPR

A 5-step strategic adoption roadmap:

-

Audit & Plan: Use anEPR Consultantto audit packaging footprint and innovation opportunities.

-

Register: Work with anEPR Registration Consultantsubmit documents and fees efficiently.

-

Design & Pilot: Develop recyclable packaging, conduct pilot take-back projects.

-

Operate & Report: Use aPlastic EPR Return Consultantfor certificate collection and annual filing.

-

Scale & Market: Access plastic credit systems, promote recycled-content credentials.

This system turns compliance into innovation, brand appeal, and circular leadership.

Conclusion

EPR for Plastic:EPR Registration ConsultantA Strategic Tool for Sustainable Innovationredefines compliancenot as a burden, but as a source of value. By embedding EPR into product design and operations, supported by expert consultants and digital infrastructure, companies can achieve regulatory certainty, cost savings, market differentiation, and positive environmental impact. As the plastic credit market grows and global standards rise, EPR becomes essential for forward-thinking brands tapping into circular economy advantages.

Let me know if you'd like actionable templates, case studies, or tailored industry insights!

FAQs

Q1: What is Plastic Waste EPR?

Extended Producer Responsibility makes producers financially and operationally responsible for post-consumer packaging, driving design and operational change

Q2: Why is EPR a strategic tool?

It embeds environmental costs upstream, incentivizing recyclable packaging, material efficiency, and circular value chain innovations.

Q3: What is EPR Registration for Plastic?

It is the formal approval process via CPCB/SPCB portals, involving documentation, fee payment, and registration for compliance.

Q4: Who is an EPR Consultant?

Experts guiding strategy, design, partner selection, and cost savings tied to EPR goals and circularity.

Q5: Why engage an EPR Registration Consultant?

They manage the admin, documents, and liaison work with regulatorscutting delays and errors.

Q6: What does Plastic EPR Government Fee cover?

Covers registration + 25% annual processing, funding waste management infrastructure sees above.

Q7: Whats a Plastic EPR Return Consultant?

They collect recycling certificates, verify compliance, and file reports to regulators.

Q8: Who is the Number 1 consultant in EPR?

Consultants with the best track record in compliance, innovation facilitation, and cost optimization.

Q9: How can EPR drive sustainable innovation?

By encouraging new materials, disassembly, take?back systems, recycled-content mandates, and eco-conscious models

Q10: What are real-world benefits?

From patent boosts to recycling rates, job creation, savings, and stronger brand positioning.