How Powder Coated Aluminium Extrusions Improve Durability & Aesthetics

The materials that are highly valued by modern construction and manufacturing sectors are all the time associated with strength, beauty, and longevity. The powder coated aluminium extrusions are among the most revolutionary solutions that have come up. Such an advanced technology turns simple aluminium profiles into efficient components which perform strongly both in durability and aesthetic values. The combination of the natural quality of aluminum with the cutting edge technology of powder coating facilities results in products that can survive the elements but never lose their beauty. Aluminium powder extrusions have become the gold standard be it in architectural facades, in automobiles components or in any respect in the professional world where one cannot afford to skimp either in quality or in the look.

1.The Science Behind Powder Coating Technology

Powder coating is a highly advanced electrochemical procedure that is by method much different as compared to conventional liquid paints. This method entails using particles of dry powder that are applied to the electrically charged surfaces of aluminium to form an electrostatic bond which holds evenly on the surfaces. After applying the coated extrusion is then heated in a special heated oven under control usually up to ranges of 160-200 o C. The resultant process is a chemical reaction termed as cross-linking, during which powder particles fuse together at the combination point by melting. The resultant coating is chemically bonded to the aluminum substrate and the outcome is a form of protective barrier which is much more durable than the common paint finishes used.

2.Superior Protection Against Environmental Damage

Manufactured goods and other building materials always face threats posed by the environment but powder coated aluminium extrusions manage to resist all these challenges in an exemplary manner. The coating serves as an effective protection against ultraviolet radiation and thus it cannot be degraded and faded as it is experienced on the untreated materials. The rain, snow and humidity cannot get into the sealed surface which will remove the fears of corrosion and water damages. The non porous coating can resist these chemical pollutants that exist in the urban areas such as acid rains and the industrial fumes. The coating has flexibility to absorb temperature changes that expand and contract materials that will resist cracking and peeling off.

3.Enhanced Resistance to Physical Wear and Tear

Frequent handling and exposure to the environment gives materials different types of physical stress and the durability factor plays an important role in selecting a material. The resistance to scratches, chips and abrasions that would rapidly destroy painted surfaces is quite striking on powder coated aluminium extrusions. The durability of the coating is high due to the hardness and elasticity of this coating that makes it cope with little loading without exposing any signs of damage giving it an immaculate look even in busy areas. Routine cleaning and muster activities are likely to dull the traditional finishes given time but have no similar effects on powder coated surfaces. The mechanical resistance of the coating applies to the thermal cycling as well where other types of finish may crack or come apart due to repeated heating and cooling.

4.Aesthetic Versatility and Design Freedom

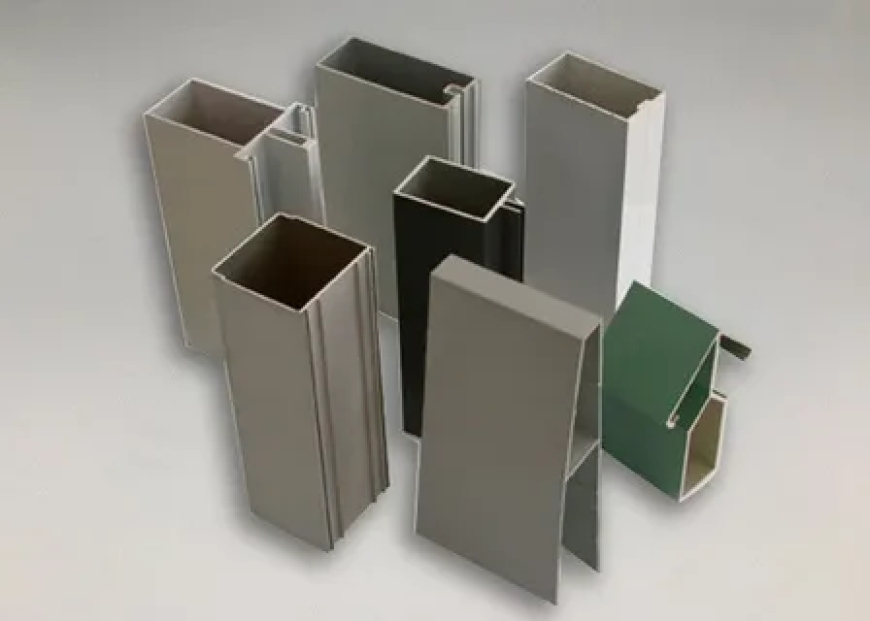

Seeing that the visual effects available to powder coating technology are practically infinite, the creativity of the designer and the architect are truly free to be expressed in ways that are not restricted by their technical possibilities. There are options available with colors in the whole range, in the light shades and at the same time with the possibilities of obtaining accurate color matching to maintain brand consistency or according to architectural specification needs. The surface textures can go smoothly to gloss-free ones, with the perspective of forming metallic effects, textured lines, and even wood-grains. Special effects that can be provided during the coating process include changing coloring to changing-colored coatings, fluorescent material and anti-graffiti surfaces. One can obtain different depth impressions and a layered effect that cannot be obtained by using normal painting techniques with the multiple layers of coating.

5.Long-Term Cost Benefits and Value

The cost benefits of powder coated to aluminium extrusions are world wide and not limited to the up-front cost of material and they have built up significant value in the life cycle of the product. Less maintenance requires less labor and does not have to be replaced regularly, which is one of the factors that is especially significant in the long term. This resistance to fading and weathering means that the coating does not require repainting, a process that is costly as well as disruptive in the context of commercial and residential uses of paints. Benefits of energy efficiency are perceived because the coating helps reflect heat and is thermally stable which makes building applications help it save in cooling cost.

6.Environmental Sustainability and Eco-Friendly Benefits

Contemporary environmental awareness requires the use of technologies and materials that reduce the burden on the ecology, and the powder coating technology has a great range of sustainable benefits. Coating also yields no significant volume of volatile organic compounds (VOCs) so the issue of air pollution due to traditional paint systems is also eliminated. The overspray powder is recoverable and recyclable where the efficiency rates are up to 98 percent and less than one percent waste is generated. Powder formulations eliminate the risks of environmental contamination and safer working conditions of manufacturing personnel since they do not contain hazardous solvents. Usage of energy in the coating process may be lessened compared to that of liquid paint systems as a result of shorter drying periods, as well as more efficient heat transmission.

Conclusion

Powder coated aluminium extrusions are an optimum combination of durability, attractiveness, and sustainability that gives satisfaction to the stringent demands of the contemporary construction and production sector. JM Aluminium architects, engineers, and designers cannot live without the use of the technology because its technology has a unique aspect of offering better security in protecting the environment and unlimited designing capabilities.